Lorch Lathe Instruction Manual

- Manuals of various lathe makes and models. Skip to main content. Lorch B30LZ & B30LZS plaquette.pdf download. MOMAC SF200 & SF230 part1.pdf download. MOMAC SF200 & SF230 part2. EMCO Super 11 CD Instruction Manual_jp2.zip download.

- Lorch mandrel headstock bed orientation. At some manuals on Steffen. Was reversed because I always used the Lorch Schmidt one with the Lorch lathe.

- Forum Actions

- Quick Links

Thread Tools

Display

- Conrad HoffmanTitanium

- Join Date

- May 2009

- Location

- Canandaigua, NY, USA

- Posts

- 2,786

- Post Thanks / Like

- Likes (Given)

- 133

- Likes (Received)

- 1200

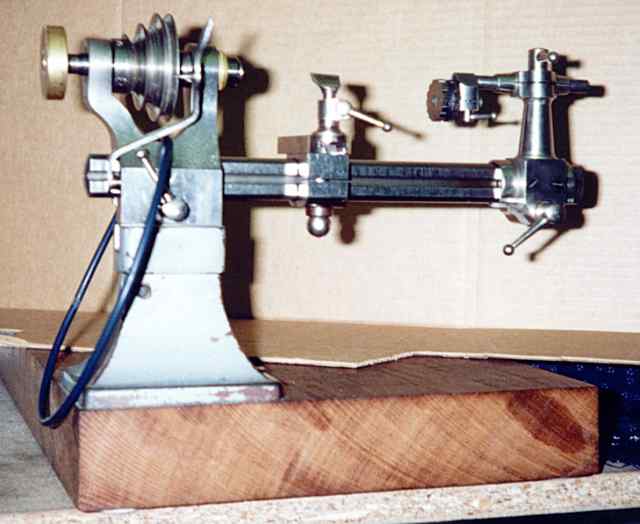

Date of Lorch jeweler's lathe

Picked up a nice little 6mm Lorch jeweler's lathe with the D-rail. Headstock is on the left and it has both a compound and a T-rest. The compound is plated and has twin slots. Tony's site suggests it might be around 1918, but there seem to be all sorts of variations on these things. Is there any way to date them with more precision? Mine may also be a Frankenlathe, as the headstock and tool rest appear to be painted, and the compound and tailstock are nickel plated. Amazingly, the taper bearings seem to be in excellent shape. Finally, who ever thought that 0.75 mm pitch lead screws were a good idea? I've read most of what I can find on the 'net, but I'm not very knowledgeable about these things.

- Aluminum

- Join Date

- Oct 2009

- Location

- UK

- Posts

- 164

- Post Thanks / Like

- Likes (Given)

- 44

- Likes (Received)

- 233

hello Conrad, that's a tough one - for it's easy to believe that dating a 'Geneva' must be the most difficult and uncertain of all. Once past their first 20 years or so of production (that began 1859 with the distinctive original Moseley) the design was so standardised that ones made 60 years later are hardly any different. For example: 'A notable milestone in the evolution of the watchmaker's lathe, the Lorch Triumph, with its light build but highly practical, easy-to-use design, probably did more than any other to popularise the 'Geneva' type, First seen in the Company's 1890 catalogue, it is believed to have reached production slightly earlier (Lorch was founded in 1885) with 'Triumph' being the maker's own model designation, not that used by a UK or other overseas' importer.Originally Posted by Conrad HoffmanPicked up a nice little 6mm Lorch jeweler's lathe with the D-rail. Headstock is on the left and it has both a compound and a T-rest. The compound is plated and has twin slots. Tony's site suggests it might be around 1918, but there seem to be all sorts of variations on these things. Is there any way to date them with more precision?.

Available for many years with a choice of a standard (No. 19) or a distinctive swivelling headstock (No. 19b) with overhung spindle pulley, it was to continue in production (alongside a wide variety of other models) for seven decades, eventually being discontinued in the early 1950s.'

See: http://www.lathes.co.uk/watchmaker and http://www.lathes.co.uk/lorchtriumph/ - Conrad HoffmanTitanium

- Join Date

- May 2009

- Location

- Canandaigua, NY, USA

- Posts

- 2,786

- Post Thanks / Like

- Likes (Given)

- 133

- Likes (Received)

- 1200

Tony, infinitely grateful for your excellent site! I guess we can say with certainty that the lathe is newer than 1885 and older than I am. The headstock has the pulley in the middle and simple oil holes. No swivel. I'll post a couple pictures when I have a chance. Holding the thing, it radiates a sort of 1930s vibe, but I could be way off in either direction. The box is the older one shown on the Triumph page, but with no front Triumph plate and with a faint star pattern on the (cracked) top. I've got a fair number of collets, the 3-jaw faceplate with a pump center and five stepped collets, plus a couple shellac type plates and holder. I've got the male/female center tailstock, but nothing that can presently hold a chuck or other tool. I'm going to spend some time making a proper tool holder for the compound and a few other things just to try it out. Thanks!

- Aluminum

- Join Date

- Oct 2009

- Location

- UK

- Posts

- 164

- Post Thanks / Like

- Likes (Given)

- 44

- Likes (Received)

- 233

Hi Conrad, if you can find another - or others - that's the way to build up the accessory collection. When it's complete ( .. it never will be ...) gather up the surplus and pop it on you know where. As usual buying a 'boxed set' can be far less expensive than acquiring items one by one. Off the main subject but associated with the advice, an acquaintance likes 50 cc Itom motorcycles (skin-rice-pudding-won't comes to mind so goodness knows why). He started buying up wrecks for spares and now has nineteen of them, all pristine. Divorced, of course.

- Conrad HoffmanTitanium

- Join Date

- May 2009

- Location

- Canandaigua, NY, USA

- Posts

- 2,786

- Post Thanks / Like

- Likes (Given)

- 133

- Likes (Received)

- 1200

Hi Tony, A good friend and excellent machinist nearby collects and restores vintage Triumph motorcycles. His shop makes reproduction and re-engineered parts for them. He's the one I got the Lorch from. Here's an example of the sort of parts he can make, and a couple bikes.

Last edited by Conrad Hoffman; 10-23-2017 at 09:32 PM.

- Conrad HoffmanTitanium

- Join Date

- May 2009

- Location

- Canandaigua, NY, USA

- Posts

- 2,786

- Post Thanks / Like

- Likes (Given)

- 133

- Likes (Received)

- 1200

Here's a shot of the Lorch. The flash makes it look worse than it looks in person- the plating is actually fairly shiny. I believe the headstock, however, is painted.

- Aluminum

- Join Date

- Mar 2017

- Country

- UNITED STATES

- State/Province

- Pennsylvania

- Posts

- 143

- Post Thanks / Like

- Likes (Given)

- 2

- Likes (Received)

- 58

Are the bed bars for the 8mm and 6mm lathes the same size? Curious because I've never seen a 6mm Lorch with a cross slide.

If you want to be the coolest kid on the block, get a handwheel and start making balance staffs entirely by hand. - Conrad HoffmanTitanium

- Join Date

- May 2009

- Location

- Canandaigua, NY, USA

- Posts

- 2,786

- Post Thanks / Like

- Likes (Given)

- 133

- Likes (Received)

- 1200

This 6 mm rail is 19.97 mm diameter. No idea about others. The lathe is plenty robust for 6 mm collets, but I do question mounting the heavy 3-jaw chuck on such. OTOH, if they made the chuck smaller it might not be very useful. As for making balance staffs, well, everything was made by hand at some point. I've got the Daniels book and wish I had some of the equipment in his shop. Another neat one is this lady- Memoria Technica

- Titanium

- Join Date

- Mar 2001

- Location

- Switzerland

- Posts

- 2,507

- Post Thanks / Like

- Likes (Given)

- 2223

- Likes (Received)

- 1069

I'll never understand why some of the Lorchs had .75 screws on the slide. Often they go backwards too.

I believe the 8mm and 6mm use the same bed. My old boss had a 6mm with cross slide. - Aluminum

- Join Date

- Mar 2017

- Country

- UNITED STATES

- State/Province

- Pennsylvania

- Posts

- 143

- Post Thanks / Like

- Likes (Given)

- 2

- Likes (Received)

- 58

Yes, I have an 8mm with the right hand headstock and the leadscrews are backward which is pretty damn annoying. As for the pitch of the screw, I don't believe the dials were really meant to be used and the pitch is just something fine enough. Geneva pattern lathes were mainly designed to be used with a graver, IMHO which is one of their big strengths when compared to American (ww) pattern lathes.

- Aluminum

- Join Date

- Mar 2017

- Country

- UNITED STATES

- State/Province

- Pennsylvania

- Posts

- 143

- Post Thanks / Like

- Likes (Given)

- 2

- Likes (Received)

- 58

You don't need fancy equipment to do watch and clockmaking, just hand skills. I watched Peter Bonnert (sp? Coauthor of the standard carriage clock book) make a new balance staff for a platform with a 8mm Lorch and a couple of gravers while he was chatting away. He didn't use any measuring tools either. All measurements were made by comparison and fitting using trial and error.

- Conrad HoffmanTitanium

- Join Date

- May 2009

- Location

- Canandaigua, NY, USA

- Posts

- 2,786

- Post Thanks / Like

- Likes (Given)

- 133

- Likes (Received)

- 1200

Ah, trial and error, the same process I use for all my machining!

Yes, I've got 0.75 mm pitch screws and they're right handed, so they 'turn backwards' so far as tool motion is concerned. - Stainless

- Join Date

- May 2011

- Location

- southern in.

- Posts

- 1,411

- Post Thanks / Like

- Likes (Given)

- 1890

- Likes (Received)

- 370

Fascinating, thanks for sharing.Originally Posted by Conrad HoffmanThis 6 mm rail is 19.97 mm diameter. No idea about others. The lathe is plenty robust for 6 mm collets, but I do question mounting the heavy 3-jaw chuck on such. OTOH, if they made the chuck smaller it might not be very useful. As for making balance staffs, well, everything was made by hand at some point. I've got the Daniels book and wish I had some of the equipment in his shop. Another neat one is this lady- Memoria Technica

JH

Pultra Lathe Manual. Smart and Brown's range of lathes, parts, servicing and operators manuals. E-MAIL tony@lathes.co.uk The Pultra Precision lathe. Pultra Home Page Early Pultra 'P' Manuals and Sales Literature is available for most Pultra Models. Makers lathe, model lathe, lorch, levin lathe. 7/16' Square Chuck Key For Lathe, 3 or 4 Jaw.

Antique Machinery and HistoryLorch Lathe Instruction Manual Manual

Top- Site Areas

- Forums

- Manufacturing Today

- Specific Machine Forums

- Open Discussion

- Commerce

- Machinery Manual, Brochure and Photo Archives

- Forum features

«Previous Thread | Next Thread»

Tags for this Thread

Lorch Lathes For Sale

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off